G.Maneger:Bill Feng

Mobeil:+86 1388 345 2222

E-mail: bill.feng@meikemold.com

hipaul@meikemold.com

leo.huang@meikemold.com

Website:www.meikemold.com

Director:Ms.Lian

Tel:+86 23 6721 0599

E-mail:purchase@meikemold.com

Tel:+86 23-6728 0800

E-mail:administration@meikemold.com

PROFILES

PROFILES

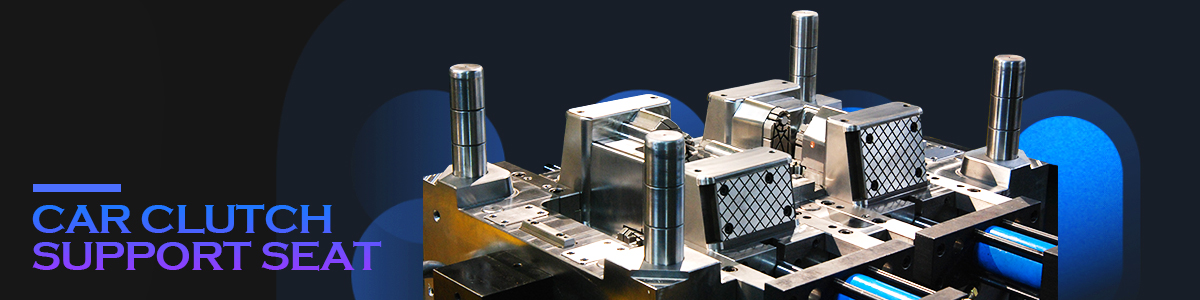

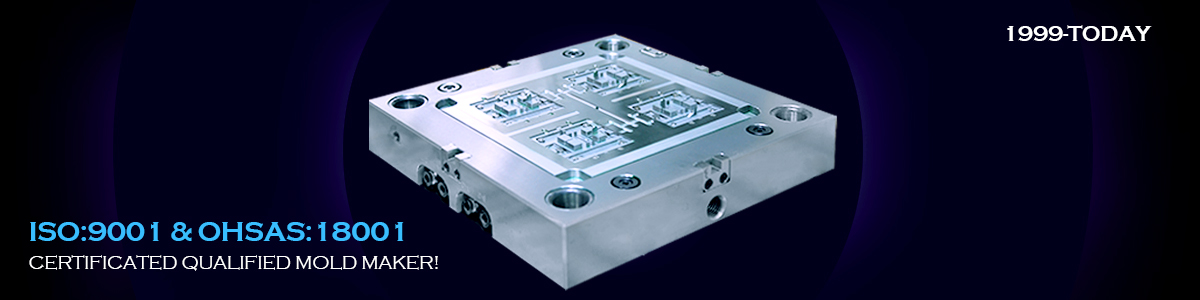

Meike’s factory is locatied in the Airport industrial park,Yubei District,Chongqing City.The company has 25-year experience of mold manufacturing and mold parts machining, and now has over 80 employees, which mainly consist of 11 employees in mold engineering, 36 employees in mold machining and 16 employees in mold assembly. More than 60% of company business are the exportation of completed molds and mold parts to Europe and North America. Our team are familar with all different kinds of mold standart in the whole world and we have the complete system of mold control、measurement analysis and reports of mold test process. Our workshops are mainly equiped with GF slow walking wire, GF mirror spark machine, fix-axis CNC, 36000 high-speed machine, 90T mold closing machine and 200T mold closing machine,etc.

NEWS

-

Trend of Mold Heat Treatment Technology

Mold heat treatment is an important process to ensure the performance of molds, which has a direct impact on the accuracy, strength, service life, and manufacturing cost of molds. It is precisely the close correlation between heat treatment technology and mold quality that enables these two technologies to mutually promote and improve in the process of modernization. - Meike ERP System offcially Launched and Running 2024-04-10

- 4 Sets New CNC Machining Center Installed 2024-03-04

- Ocean Shipment of Bulk Production and Injection Molds to Mexico 2023-11-27

- Successful Trial Of Oasis New Water Dispensor Injection Tools 2023-08-21

- Gas Auxiliary Injection Molding Parts 2023-08-15

- Meike’s Summer Business Travel to Our Partners in USA 2023-08-01

- General Electric Appliances (GEA) MRO Project Completes First Production Delivery 2023-05-23

- 6000㎡Added in Our New Factory for Building More Specilized Injection Mould Workshop 2022-09-15

FLIGHT

FLIGHT

| Flight |

| Europe---Chongqing |

|

Milan | Brussels | Manchester | Amsterdam |

| America---Chongqing |

| Australia---Chongqing |

|

Auckland | Melbourne | Sydney | Wellington |

|

Asia---Chongqing |

| Bangkok | Bali | Fukuoka | Jakarta | Macao |

| Logistics |

| Europe---Chongqing |

| America---Chongqing |

| Australia---Chongqing |

|

Asia---Chongqing |

| Port of Yokohama | Port of Kobe | Osaka |

AUTO

AUTO

APPLIANCE

APPLIANCE

Inquiry

Inquiry

What's App:+86 15360439294

WeChat:15360439294

Skype:8615360439294

PROFILES

公司简介手机端

PRODUCTS

NEWS

2024-04-18

© 2020 CHONGQING MEIKE MOLD ENGINEERING CO.,LTD 渝ICP备16009365号 POWERED BY:300.cn

© 2020 CHONGQING MEIKE MOLD ENGINEERING CO.,LTD

渝ICP备16009365号 POWERED BY:300.cn

Phone

Phone WhatsApp

WhatsApp  E_mail

E_mail