Inquiry

Inquiry

What's App:+86 15360439294

WeChat:15360439294

Skype:8615360439294

Gas-assisted injection molding technology put into use formally

- Categories:Company news

- Author:

- Origin:

- Time of issue:2017-02-11 14:46

- Views:

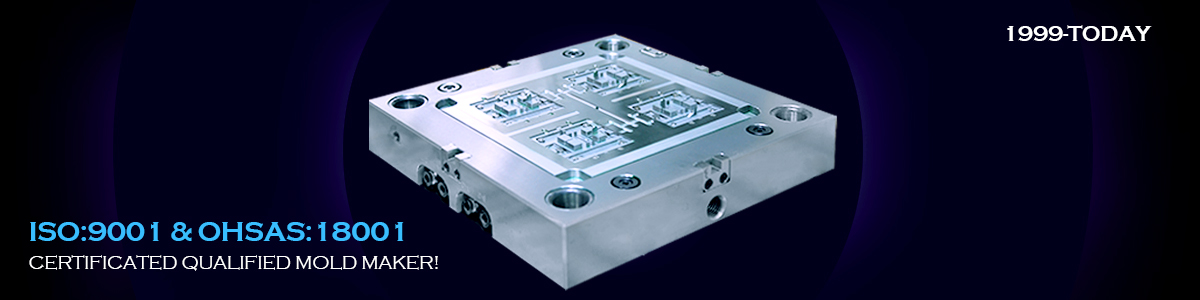

(Summary description)Gas-assisted injection molding with many advantages such as low injection pressure, products with small warpage, high quality surface and easy to process parts with big different wall thickness. In recent years, gas-assisted injection molding develops fast and it has been applied to plastic products in business area about 20 years in developed countries.

Gas-assisted injection molding technology put into use formally

(Summary description)Gas-assisted injection molding with many advantages such as low injection pressure, products with small warpage, high quality surface and easy to process parts with big different wall thickness. In recent years, gas-assisted injection molding develops fast and it has been applied to plastic products in business area about 20 years in developed countries.

- Categories:Company news

- Author:

- Origin:

- Time of issue:2017-02-11 14:46

- Views:

© 2020 CHONGQING MEIKE MOLD ENGINEERING CO.,LTD 渝ICP备16009365号 POWERED BY:300.cn

© 2020 CHONGQING MEIKE MOLD ENGINEERING CO.,LTD

渝ICP备16009365号 POWERED BY:300.cn

Phone

Phone WhatsApp

WhatsApp  E_mail

E_mail